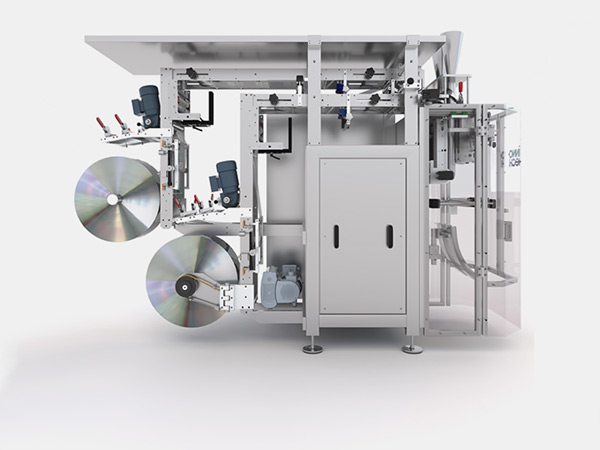

REVO SDR Twin Tube

CONTINUOUS HIGH SPEED

REVO SDR – For highest performance up to 500 Bags / min

- For all usual bag types

- Low-wear welding and sealing systems

- Heat sealing

- Safely sealed seams thanks to high sealing jaw pressure – cross jaw drive with servo motor, variable opening width (storable in the program), welding and sealing pressure adjustable (storage optional)

- Menu-supported operation via color touch screen, IPC control, memory for 300 programs (optionally up to 1,000), different levels of access (password protected), data backup / transfer via USB, memory card or Ethernet interface optional

- All models with SIEMENS PLC (or B&R)

- Safe film tracking by standard automatic film tracking control

- Easy to clean and easily accessible, no painted parts

- Cabinet made of stainless steel

- Low maintenance, high availability, minimized set-up times

- Synchronization with multi-head weighers without loss of performance

- Intermittent mode for the production of high-quality flat-bottom bags

- Quick-change film roll system with pneumatic clamping shafts

- Vacuum film transport (option)

- Labeler, printer (options)

- Remote maintenance (optional)

- Various sealing profiles

- Euro and round hole perforations available according to customer specification

| Type REVO SDR Twin Tube | 2500 REVO SDR | 3800 REVO SDR |

|---|---|---|

| Bag width | 30-90 mm | 60-120 mm |

| Bag length | 200 mm | 550 mm |

| Bag types | Pillow bag | |

| Films | Commercial mono- and multilayer films, polyethylene | |

| Max. mech. performance | 250 Cycles/min (500 Bags / min) | |

| Electrical connection | 230/400 V – 50 Hz, 3 phases N/PE | |

| Pneumatic connection | 6 bar constant, oil- and condensate-free | |

| V2A / Alu | •/• | •/• |